What are the types of filter elements?

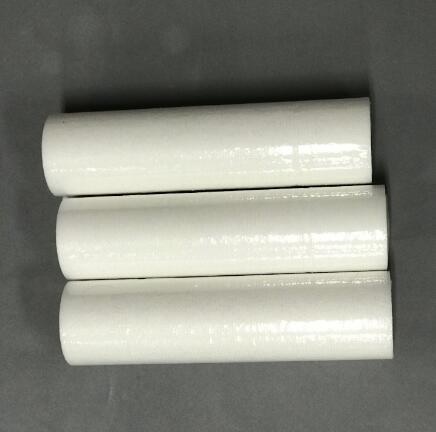

1.) PP Filter Element

PP filter element is also called PP melt-blown filter element. The melt-blown filter element is made of polypropylene ultra-fine fibers by thermal melting and entanglement. The fibers randomly form a three-dimensional microporous structure in space. Precise and fine filtration in one, can intercept impurities of different particle sizes. The accuracy range of the filter element is 0.5-100μm, and its flux is more than 1.5 times that of the peak room filter element of the same accuracy. Different types of end cap connectors can be configured to meet the needs of various engineering installations.

2.) Wire Wound Filter Element

Refined by finely winding textile fiber yarn with good filtering performance on a porous skeleton. The yarn materials include polypropylene fiber, acrylic fiber, absorbent cotton fiber and so on. By controlling the tightness and thinness of the yarn during winding, water purifier filter elements with different precisions can be made, which can effectively remove suspended solids, particle impurities, etc. of various liquids, and have a high purification effect on various liquids. Pleated filter

3.) Foldable Microporous Filter Element

The folding microporous filter element is a precision filter device made of polypropylene (Polypropylene) thermal spray fiber membrane, nylon (Nylonb) polytetrafluoroethylene (PTEE) microporous filter membrane, etc. as the filter medium. It has a small volume and a large filtering area. The advantages of high precision. The filtering accuracy can range from 0.1μm to 60μm. The end cover of the filter element is sealed and the overall structure is connected by hot melt bonding. The filter element joints are of three types commonly used internationally: 222 joints, 226 joints, and flat ports. The products have undergone strict and complete testing before leaving the factory to ensure the stable performance of the products.

4.) Activated Carbon Filter Element

There are two types of activated carbon filter elements: compressed activated carbon filter elements and bulk activated carbon filter elements.

A. The compressed activated carbon filter element uses coal-based activated carbon and coconut shell activated carbon with high adsorption value as the filter material, and is sintered and compressed with a food-grade binder. The inside and outside of the compressed activated carbon filter element are respectively wrapped with a layer of non-woven fabric with filtering effect to ensure that the carbon core itself will not drop the carbon powder. The two ends of the carbon core are equipped with soft nitrile rubber gaskets, so that the carbon core is loaded into the filter cartridge. Has good airtightness.

B. Bulk activated carbon filter element. Put the required activated carbon particles into a special plastic shell, and use welding equipment to weld the end caps to the two ends of the shell, and put the two ends of the shell into the non-woven fabric for filtering. The filter ensures that the carbon core will not drop carbon powder and black water during use. According to the needs of customers, the shell end cover can be made into different types of connection ports. Interface methods are: flat pressure type, pipeline type (models: 4042, 4044, 4046, etc.).

5.) Double Section Filter

The last section: Polypropylene melt blown filter element with a precision of 5μm

Next section: Activated carbon 170g built-in granular activated carbon filter

Material: ABS, PP

Length: 250mm Outer Diameter: 70mm Flux: 8L/S Total flux: 6-8T

Activated carbon index: strength>90; iodine value (mg/g)>950; methylene blue value (mg/g)>120

6.) Ceramic Filter

The ceramic filter element is made of pure natural physical materials, so there will be no secondary pollution during the use of the water purifier. At the same time, unlike the ceramic filter element of a pure water machine, it will remove all the minerals that are not in it. It retains beneficial minerals in the water, while effectively removing mud, sand, bacteria, rust, never clogging, long service life, and excellent filtering effect. At the same time, it is not afraid of clogging and can adapt to very poor water quality. At present, the ceramic filter element with the highest filtration accuracy in the world is a dual-control membrane ceramic filter element with an average pore size of 0.1μm. The water filtered by the filter element can be consumed without boiling, which fully meets the national standard for direct drinking water.

7.) Resin Filter

Resin is a porous, insoluble exchange material. There are millions of tiny plastic balls (beads) in the resin filter element of the water softener, all of which contain many negative charges exchange positions that absorb positive ions. When the resin is in its nascent state, these charge exchange sites are occupied by positively charged sodium ions. When calcium and magnesium pass through the resin storage tank, they come into contact with the resin beads and replace the sodium ions from the exchange position. The resin preferentially binds the more strongly charged cations, and the charge of calcium and magnesium ions is stronger than that of sodium ions. Replace the sodium cations and then pass down the resin” bed, out of the water softener, so that the water softener sends out “soft” water. Finally, all the resin exchange positions are occupied by calcium and magnesium and can no longer work.

8.) Titanium Rod Filter Element

The titanium rod filter element has excellent properties such as corrosion resistance, high temperature resistance, high strength, easy filtration accuracy, and easy regeneration; the titanium filter element is formed from titanium powder through forming and high temperature sintering, so the surface particles are not easy to fall off; the use temperature in the air It can reach 500~600℃; it is suitable for filtration of various corrosive media, such as: filtration of hydrochloric acid, sulfuric acid, hydroxide, sea water, aqua regia, and chloride solutions such as iron, copper, and sodium. It has excellent mechanical properties and can be machined for cutting and welding. It has high compressive strength and internal pressure damage strength of up to 2MPa or more; its filtration accuracy is easy to ensure, even if it works under high temperature and high pressure, the pore size will not be deformed. The porosity can reach 35-45%, the pore size distribution is uniform, the dirt holding capacity is large, and the regeneration method is simple, and it can be reused after regeneration.

9.) RO Reverse Osmosis Filter Element

The filter element adopts RO reverse osmosis membrane. Reverse osmosis technology: The original text of reverse osmosis is REVERSE OSMOSIS, which is a collection of scientists from the United States National Aeronautics and Space Administration, with government support, and spent billions of dollars in research for many years. The principle of reverse osmosis is to apply a pressure greater than the natural osmotic pressure on the raw water side, so that water molecules reverse osmosis from the high concentration side to the low concentration side. Since the pore size of the reverse osmosis membrane is much smaller than hundreds or even thousands of times that of case viruses and bacteria, all kinds of viruses, bacteria, heavy metals, solid soluble matter, polluting organic matter, calcium and magnesium ions, etc. cannot pass through the reverse osmosis membrane. So, as to achieve the purpose of water softening and purification.

10.) Stainless Steel Filter Element

Features of Stainless-Steel Filter Element:

1, Good filtration performance, uniform surface filtration performance for 2-200um filtration particle size

2, Good corrosion resistance, heat resistance, pressure resistance and abrasion resistance;

3, The stainless-steel filter element has uniform and precise filtration accuracy;

4, The flow rate per unit area of the stainless-steel filter element is large;

5, The stainless-steel filter element is suitable for low temperature and high temperature environment. It can be used again after cleaning, no need to replace.

Application: Petrochemical, oilfield pipeline filtration; fuel oil filtration equipment, engineering machinery equipment; water treatment industry equipment filtration; 7 pharmaceutical and food processing fields; rated flow 80-200l/min working pressure 1.5-2.5pa filter area (m2) 0.01 -0.20 Filtration accuracy (μm) 2-200 μm Filter material Stainless steel woven mesh Stainless steel perforated mesh is used to remove water in the front stage of heavy oil combustion system, and can also be used for chemical liquid filtration. The precision is 100um. The filter element is stainless steel round microporous mesh. It is suitable for pre-processing and post-processing systems in the electronics, petroleum, chemical, pharmaceutical, food and other industrial sectors. Further purify the water with low suspended impurities (less than 2~5mg/L).

11.) Filter Element of Oil Filter

A variety of specifications and different material filter elements, the accuracy is from 0.5 to 80 m, to meet the processing needs of different industries and various oil products.

12.) Hydraulic Oil Filter Element

The hydraulic oil filter element is mainly used for filtering the oil in the hydraulic system to remove particles and rubber impurities in the hydraulic system to ensure the cleanliness of the hydraulic oil, so that the hydraulic system can operate normally.