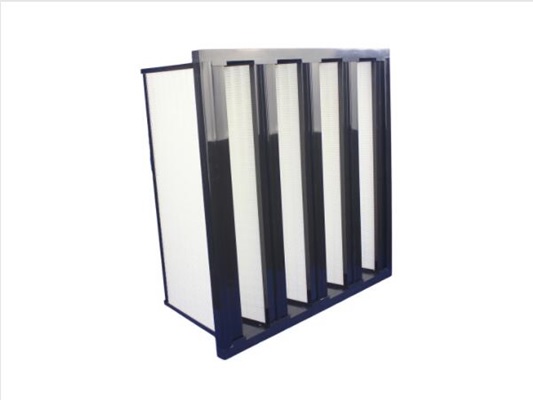

Why do customers always choose W-type sub-high efficiency filter?

W-type sub-filters are used in clean rooms, medium-efficiency filters in commercial and industrial ventilation and air conditioning systems, ventilation and air conditioning systems in high humidity environments, variable air volume ventilation and air conditioning systems, ventilation and air conditioning systems with tight installation controls, and are widely used in cleaning Room and other areas where air cleanliness is strictly required.

Gas filter is an important equipment to alleviate air pollution, and it is also an effective means. The advent of filters has attracted the attention of many manufacturers. Today, gas filters have been widely used in electronics, chemical, petroleum, food and other industries, not only to provide a high-quality environment for enterprise production, but also to protect the environment. However, there are many gas filters, such as high efficiency filters without partitions. Different filters have different functions and values.

For enterprises, choosing high-quality filters is the key. All in all, gas filters are important equipment for manufacturers. This article will briefly introduce the reasons for the popularity of gas filters.

The composition of the gas filter is relatively complex, mainly composed of filter element, backwash system, pressure control machine and other parts. The inside of the gas filter is separated by a transverse section to form a cavity. The upper part of the filter is the filter cavity, and the lower part is the backwash system. The two parts have different functions. The filter cavity is equipped with multiple filter elements according to different filter media, which can improve the utilization rate of the space, and the backwashing system can flush the filter element and prolong the service life of the filter element. When the filter is working, the air is introduced into the filter, enters the interior through the pipe, and then is filtered by multiple layers of filter materials to filter the dust particles in the air to achieve the desired filtering effect.

The backwash function of the gas filter is the key to filtering, reducing the filtering time. By detecting the inlet pressure difference, it is judged whether the filter element is saturated or not, and then it works according to the judgment result. If there are too many impurities on the surface of the gas filter, it will cause a change in the outlet pressure difference. When the changed value reaches a certain value, the backwash system will automatically turn on to blow off the impurities from the surface of the filter element. If the pressure difference between the inlet and outlet returns to the normal value, the backwash system will automatically shut down, and then the contaminated material will be discharged.

The above is a brief introduction to the filtering principle and structure of the gas filter. I think everyone should understand the reason for the popularity of the gas filter. Enterprises need gas filters mainly to protect the production environment and provide a good production environment for enterprises. I believe that with the development of science and the increasing awareness of environmental protection, gas filters will become more and more widespread. Shanghai SFFILTECH is a manufacturer of high efficiency filters without partitions. The quality of the products is reliable and I believe it can help you.