What are the special features of the high temperature resistant primary filter?

High temperature resistant primary filter is also called primary high temperature resistant filter. It is mainly used for primary filtering in high temperature environment. Different filter materials are used in different temperature environments. The filter material is generally high temperature resistant imported glass fiber, and the filtration efficiency can be Up to 90%. The temperature resistance can reach up to 500 degrees.

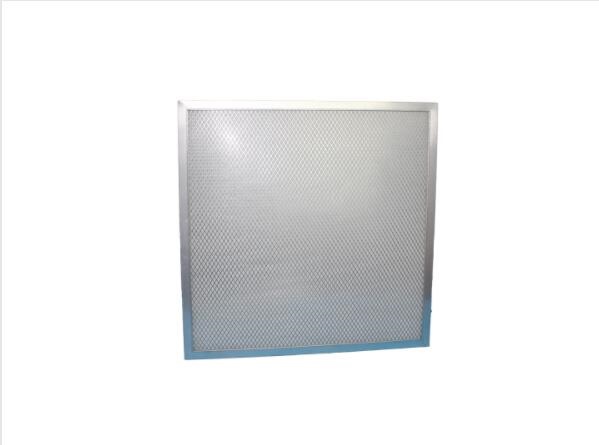

Primary Effect High Temperature Resistant Filter-Product Characteristics of High Temperature Resistant Primary Filter

1) It is made of long glass fiber and laminated in a non-woven way.

2) It has the characteristics of long fiber: the fiber has good strength, good elasticity, and it does not compress the filter material due to wind resistance, which affects the dust holding capacity.

3) The filter has good chemical resistance and low moisture absorption.

4) Optional temperature resistance: 350C, 450C. 680C

5) Filter level: G3, G4, F5

6) Standard size: 595mmx595mmx46mm or 595mmx595mmx25mm

Primary Effect High Temperature Resistant Filter Structure

1) Glass fiber outer summer aluminum mesh with different diameters, all of which belong to the outer frame.

2) The filter material is made of high-temperature resistant glass fiber imported from Japan through a special process. Long glass fiber and short glass fiber can be selected in different environments. Galvanized sheet, aluminum alloy or stainless steel can be used as the outer frame. The high temperature can reach 400C.

3) An aluminum expansion mesh can be used to cover the filter material, which can effectively support the filter to withstand large air volume and not easily deform.

Use of Primary High Temperature Resistant Filter

1) General coarse dust filtration treatment.

2) Hot-air high-temperature oven or high-temperature oven in paint factory.

3) Coating production lines for automobiles and home appliances, as well as various hot-air drying rooms that need to be purified, coating equipment and air-conditioning systems.