How to install the air filter?

In clean workshops, purification equipment and purification air conditioners, in order to ensure the air cleanliness effect, the air filters inside must be replaced at regular intervals. Now, most purification areas install air filters at the ceiling air supply ports, installation methods and pre-installation confirmation completely determines whether there is a leak in the HEPA filter. The pre-installation confirmation is more efficient and provides effective objective conditions during installation, so you must pay attention to methods and skills during installation.

Matters Needing Attention

The high-efficiency filter must be replaced after the air supply of the air-conditioning system is stopped. The gasket between the filter and the connecting frame must be tight and leak-free to ensure the filtering effect.

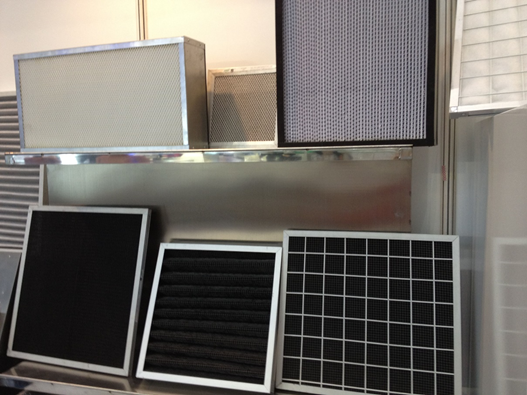

Tools/Materials

Before installing the air filter, the clean room must be cleaned, wiped, and purified. If there is dust inside the air conditioning system, it should be cleaned and wiped again to meet the cleaning requirements. If a high-efficiency filter is installed in the technical interlayer or suspended ceiling, the technical interlayer or suspended ceiling should also be thoroughly cleaned and wiped.

It should be cleaned before installation. The air outlet of the air filter needs to be installed and replaced in the clean room, and the seam between the flange of the air outlet and the ceiling plate should be sealed. Install and replace the air outlet of the high-efficiency filter in the technical interlayer. Before installation, the short pipe should be embedded in the civil construction. If there is any crack between the short pipe and the ceiling plate, it must be sealed. If the surface coating of the tuyere is damaged, it shall not be installed. After the air outlet is installed. It should be connected with the air duct immediately, and the open end should be sealed with plastic film and tape.

After the clean room and purification air conditioning system meet the cleaning requirements, the purification air conditioning system must be tested. After continuous operation for more than 12 hours, install the air filter immediately after cleaning and wiping the clean room again.

The filter packaging must be unpacked at the installation site for visual inspection, including whether the filter paper, sealant and frame are damaged; whether the side length, diagonal and thickness dimensions meet the requirements; whether the frame has burrs and rust spots (metal frame). Yes, there is no product certificate, whether the technical performance meets the design requirements. Then check for leaks. Those that have passed inspection and leak detection should be installed immediately. During installation, reasonable allocation should be made according to the resistance of each filter. For one-way flow, the difference between the rated resistance of each filter and the average resistance of each filter should be less than 5% between the filters on the same air outlet or air supply surface. High-efficiency filters with cleanliness levels equal to and higher than class 100 cleanrooms.

When installing the high-efficiency filter, the arrow on the outer frame should be in the same direction as the airflow. When it is installed vertically, the crease seam of the filter paper should be perpendicular to the ground. When the sealing between the filter and the frame adopts the methods of sealing gasket, self-adhesive, negative pressure sealing, liquid tank sealing and double ring sealing, the packing surface must be, filter frame surface and frame surface and liquid tank wipe clean.

Precautions

Apply glass glue evenly on the sealing strip. When connecting the filter to the static pressure box, the surrounding force should be uniform. After 24 hours, the glass glue has dried before running the purification system.

When transporting and storing the filter, it should be placed in the direction marked by the manufacturer. During transportation, it should be handled with care to prevent violent vibration and collision, so as to avoid man-made damage.