What kinds of structures do air filters generally have?

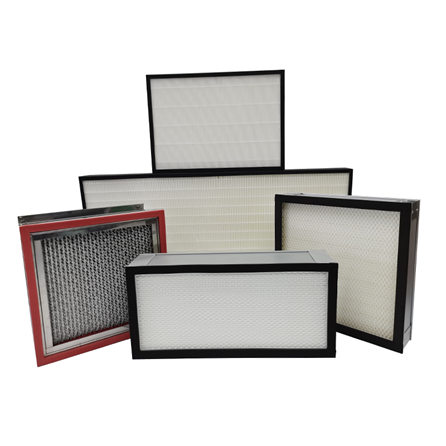

Air filters are generally used in various work and cleaning workshops. The function is to filter out dust and impurities in the air and also to separate liquid water and liquid oil, mainly to ensure the cleanliness of the workshop. There are also many types of air filters. Next, I will introduce the structure of several of them.

Air Filter Structure – Brief Introduction of Oil Bath Air Filter Structure

Oil bath air filters are especially important in environments with high dust concentrations. Generally, the dust filter devices used in fluid machinery (air compressors, compressors, vacuum pumps, fans, etc.) are mostly commonly use wire mesh type, Raschig ring type, paper and fiber material filtration.

The oil bath air filter is cylindrical, and the cylinder is divided into three parts: the outer cylinder, the inner cylinder, and the air outlet. The upper part of the interior is a swirl plate (or guide vane) and a filter screen, the lower part is connected to the outer cylinder, and the bottom of the cylinder is filled with general fluid machinery oil (waste oil).

Air Filter Structure – Brief Introduction of Compressed Air Filter Structure

Compressed air filter is made of high-quality aluminum alloy, epoxy resin powder sprayed inside and outside to improve pressure resistance and corrosion resistance, O-ring seal leak-proof ring, rib-type housing for easy use of elbow wrenches, differential pressure gauge. Prompt the best time to replace the filter element, improve the filter as much as possible. The investment utilization rate of the filter and reduce the pressure drop. The liquid level indicator can be used to visually monitor the liquid level and pay attention to maintenance at any time. The working pressure is 0.2–1.3MPA, the working pressure Temperature < 66.

Air Filter Structure – A Brief Introduction to the Structure of the Baffled Air Filter

The filter material with baffle filter is separated and folded by special automatic equipment, which is made of wrinkled aluminum foil. The management of the production process and strict testing ensure the quality of the product. The folded view filter can accumulate larger dust at the bottom of the folded view, while the sides can effectively filter other fine dust. In general, the deeper the folded field, the longer the lifespan. The use of this filter does not need to change the design of the original air-conditioning box. The efficiency is better than the traditional flat filter, and the life of the rear high-efficiency filter can be extended.

Oil bath air filters, compressed air filters, and air filters with baffles are several types of air filters commonly used on the market. Because of their strong filtration capacity, they are mainly used in electronic, pharmaceutical industries and hospitals. Industries with particularly high air environment requirements.