What is the knowledge of glass fiber bag filter?

Glass Fiber Bag Filter is Also Called Glass Fiber Bag Filter

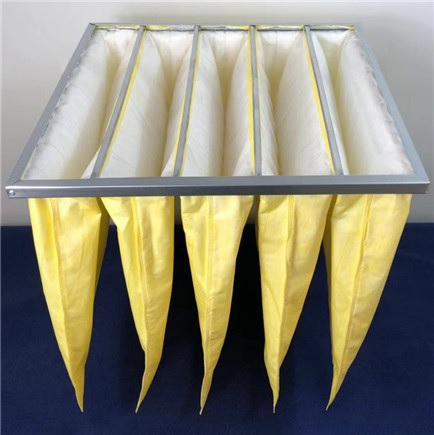

Glass fiber bag-type medium-efficiency filters are F7 and F8 grades respectively. Glass fiber bag-type medium-efficiency filters generally use non-woven fabrics and imported glass fibers as filter materials, and galvanized sheets or aluminum alloy frames. It has the advantages of large dust holding capacity, large air volume, small resistance and repeatable cleaning. Glass fiber bag filter is widely used in optical electronics, instrumentation, food and beverage, biological laboratory and other industries; (F7 grade F8 high temperature resistant washable fiberglass pocket Filter Bag manufacturer).

The fiber bag filter is made of ultra-fine synthetic fiber with a special process to avoid the possible harm to the human body caused by the old glass fiber material. The filter material contains anti-static fiber, which is particularly good for filtration of air dust particles. High performance and long service life.

1.) Using ultra-fine chemical fiber filter material, the dust holding capacity is large and the efficiency is stable during the service cycle.

2.) Melt-blown ultra-fine synthetic fiber filter material, and the optimized “V”-shaped filter bag structure is selected, with low resistance and long service life.

The glass fiber bag-type medium-efficiency filters are F7-grade glass fiber bag-type medium-efficiency filters and F8-grade glass fiber bag-type medium-efficiency filters.

Product Features of Glass Fiber Bag Filter:

1.) Good flame retardant performance, reaching UL-2 standard.

2.) The product has large dust holding capacity and long service life.

3.) U.S. ultra-fine glass fiber filter material is used to ensure the effective operation of the filter system.

4.) The filtration efficiency grade can reach – F7, F8 (EN779).

Glass Fiber Bag Filter Replacement Cycle:

1.) Under the condition of rated air volume, the filter needs to be replaced within 3-6 months;

2.) Or when the resistance of the filter reaches more than 450Pa, the filter must be replaced;

3.) If the filter uses a washable filter material, the replaced filter material can be rinsed with water or a solution containing neutral detergent, dried, and then replaced; at most two times of cleaning is allowed, that is, it must be Replace the filter with a new one; if the dust concentration in the use environment is high, the service life cycle will also be reduced.

Glass fiber bag type medium-efficiency filter is mainly used in intermediate filtration of central air-conditioning ventilation system, pharmaceutical, hospital, electronics, food, and other industrial purification, application fields: it is an ideal choice for fireproof certification enterprises, and it is also an ideal configuration commonly used in ventilation and air-conditioning systems.

Precautions for the Use of Glass Fiber Bag Filter:

Regularly check whether the air inlet surface of the filter is blocked by debris and whether the surface of the filter material is damaged; if there is any blockage on the surface, it should be removed; if the surface of the filter material is seriously damaged, it must be replaced with a new filter material or a new filter re-install.

When installing the fiber filter, it is necessary to ensure good sealing with the blank holder of the frame to prevent air leakage; do not use heavy objects to hit the surface of the filter, and do not use force to pull the surface of the filter material.

When installing the glass fiber medium-efficiency filter, the length direction of the filter bag mouth should be perpendicular to the ground to ensure the filtering effect of the air supply and increase the service life.