The secret of 400-degree high temperature resistant high efficiency filter?

The 400-degree high-temperature high-efficiency filter is also known as the 400-degree high-temperature high-efficiency air filter and the high-temperature filter. The 400-degree high-temperature high-efficiency filter is mainly used in ultra-clean ovens and other equipment and systems that require high-temperature air purification. 400 degree high temperature resistant high efficiency filter limit size: width ≤ 1220mm, length ≥ 1220mm, thickness 50~300mm.

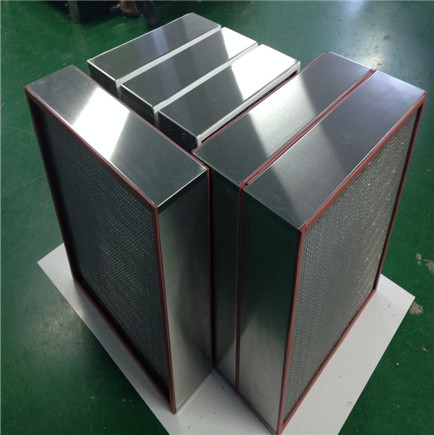

The 400 degree high temperature resistant high-efficiency filter is mainly made of high-performance high-temperature resistant ultra-fine glass fiber filter paper as the filter medium, aluminum foil corrugated sheet as the spacer, SUS304 stainless steel plate as the frame, sealed with high temperature resistant sealant. Its 400-degree high-temperature high-efficiency filter is characterized by high filtration efficiency, low resistance and good high temperature resistance.

The corrugated partition of the high temperature filter can accurately maintain the pleat spacing, and maximize the use of the filter material with less resistance. The 180 pleats on both sides of the filter material are folded to form a wedge-shaped pleat, and there are two indentations when the filter material is bent, so that it is opened into a wedge-shaped box-shaped pleat at the rear end of the separator. The wedge-shaped box-shaped pleat can be Prevent filter damage.

400 degree high temperature high efficiency filter | 400 degree high temperature high efficiency air filter material and performance:

1.) The material of the outer frame of the 400-degree high-temperature high-efficiency filter is optional, aluminum alloy profile frame, stainless steel frame.

2.) Filter material: ultra-fine glass fiber filter paper.

3.) Sealant: imported high temperature resistant glue.

4.) Separator: aluminum foil.

5.) Efficiency: 99.97%-99.999% (H13, H14) (MPPS).

6.) High operating temperature: 315℃.

400 degree high temperature high efficiency filter | 400 degree high temperature high efficiency air filter Product features:

1.) The high-efficiency filter with high temperature resistance to 400°C uses a partition design. The corrugated partition can accurately maintain the pleat spacing, and the filter material can be used to the maximum extent under small resistance.

2.) The two sides of the filter material of the high temperature resistant filter are folded at 180° to form a wedge-shaped pleat layer. When the filter material is bent, there are two indentations, which make it open into a wedge-shaped box-shaped pleat at the rear end of the separator. Pleated layers prevent filter paper breakage.

3.) Usually used in high-temperature clean ovens, high-temperature sterilization equipment and high-grade purification equipment.

400 degree high temperature high efficiency filter | 400 degree high temperature high efficiency air filter Application places:

1.) High cleanliness occasions such as aerospace, electronics, semiconductors, wafers, biopharmaceuticals, hospitals, and food processing.

2.) The terminal of the air conditioning and ventilation system (terminal filter and hot air type high temperature oven).

Intimate customization: According to any needs, tailor-made intimate products for you.

3.) High temperature coating line

4.) Clean baking room

5.) Purify the oven

6.) Food baking equipment

7.) High temperature sterilization equipment, such as: high temperature sterilization equipment in pharmaceutical factories

8.) Other ventilation and air conditioning systems with high fire protection requirements or high ventilation temperature.

400 degree high temperature high efficiency filter | 400 degree high temperature.

High Efficiency Air Filter Materials and Operating Conditions:

Filter material: superfine glass fiber filter paper

Sealant; red silica gel (250~280℃) & nbsp; ceramic glue (350~400℃).

Frame material; aluminum profile/aluminum plate/galvanized iron/stainless steel can be selected below 250℃ Galvanized iron frame or stainless steel frame must be selected above 250℃.

Separator: 0.035mm thick aluminum foil.

Sealing strip: Silicone plate (250~280℃) PTFE strip (350~400℃).

Filtration efficiency: 99.97%~99.995% @ 0.3μm

Use high temperature; 250~280℃ 350~400℃

Use higher humidity: 80%

Optional thickness of aluminum profile: 120~220mm

The 400-degree high-temperature high-efficiency filter corrugated partition can accurately maintain the pleat spacing, and maximize the use of the filter material with small resistance.

400-degree high temperature resistant high-efficiency filter The 180 pleats on both sides of the filter material are folded to form a wedge-shaped pleat layer. When the filter material is bent, there are two indentations, so that it opens into a wedge-shaped box-type pleat at the end of the separator. Cassette pleats prevent media breakage.

400 degree high temperature resistant high efficiency air filter limit size: width ≤ 1220mm, length ≥ 1220mm, thickness 50~300mm.

When using a high temperature filter, you must know the uses of the high temperature filter, so that the high temperature filter can be better used for the corresponding filtration work. At this time, the high temperature filter must be used. It has a certain understanding of its own characteristics and precautions for use.

Advantages of high temperature filter:

First of all, you should know that the filtration accuracy and filtration efficiency of the high temperature filter itself are very good. In many current production environments, the requirements for environmental cleanliness are relatively high. At this time, high-precision filtration equipment is required to carry out Corresponding filtration work provides clean air for these production sites. At the same time, the high temperature filter can also adapt to some low-precision filtration work. It can be said that the filtration range is very wide, and the filtration efficiency has also been recognized by the majority of consumer groups.

Characteristics of high temperature filter:

The characteristics of the high temperature filter itself are also very obvious, that is, high temperature resistance. Wuhan high temperature filter manufacturers found that many current production sites have requirements for the cleanliness of the filter environment, and the temperature of the production environment is also relatively high. At this time, when ordinary filter equipment is used, the filter equipment will be affected by high temperature, and its service life will be reduced. It will be shortened, and the use of high temperature resistant filters can not only maintain better filtration efficiency and filtration effect, but also the service life of the filtration equipment will not be affected at all. Such high temperature resistant filters are suitable for use in biopharmaceuticals, circuits board and food processing industries.

Precautions for the use of high temperature filters:

Of course, in the process of using high temperature filter, there are also some precautions that need to be observed. High Temperature Air Filter manufacturers remind everyone that if the work intensity is relatively high, in order to extend the service life of the high temperature filter and reduce the workload of the high temperature filter when using the high temperature filter, you can increase the Pre-filter environment. And different high temperature filters have a limit on the upper limit of the temperature they can withstand. Pay attention to the upper limit, and the temperature cannot exceed the upper limit, otherwise the quality of the high temperature filter will be damaged.

To better use the high temperature filter, it is necessary to have a certain understanding of the high temperature filter. At the same time, in order to ensure that the high temperature filter will not be damaged in the process of use, it is also necessary to pay attention to some precautions.